What Does It Mean to Be a GMP Pre-Rolled Facility?

What is a GMP Pre-Rolled Facility?

For every safe and enjoyable pre-roll on the market, there are bound to be shoddy brands that cut corners during production in order to save money. To set yourself above these facilities and showcase your hard work to your customers, you may consider becoming a GMP pre-roll facility.

In the hustle and bustle that goes into setting up a facility, proper planning and good general practice can quickly take a place on the backburner. In order to follow GMP standards, you must be willing to dedicate the time to creating and acting on a safe production plan.

Because there’s no clear federal oversight over the cannabis industry right now, it can be all too easy for companies to take advantage of the lack of regulations. By going out of your way to implement GMP into your facility, you help do your part to grow the high-quality pre-roll industry and prepare for potential federal regulation.

What Does GMP Mean?

GMP stands for Good Manufacturing Practice, a set of regulations put forward by the FDA. Published to ensure a higher standard of quality for drugs, blood, and some types of food, GMP regulations cover everything from the manufacturing to the packaging phase of a product. Specifically, GMP covers:

- Product development

- Materials

- Equipment

- Facility & premises

- Storage

- Processing

- Packaging

- Records

Due to the legal status of cannabis at the federal level, the FDA has yet to publish nationwide GMP standards for cannabis products, including pre-rolls. This has left states and business owners alike scrambling to come up with their own high-quality standards to ensure the safe production and delivery of medical cannabis.

Why Is GMP Important?

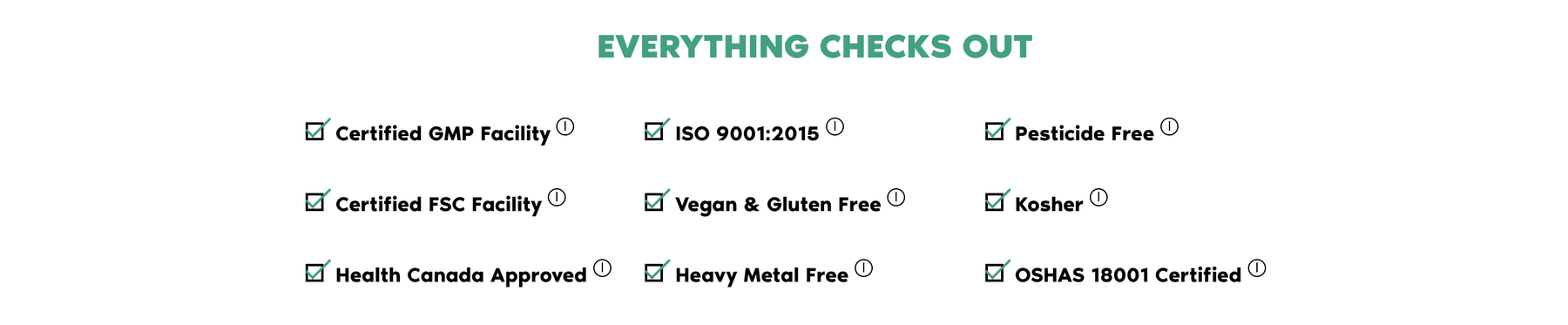

In other industries, GMP is known for acting as a level of quality control for each phase of a product’s life from materials, to creation, and finally to packaging and delivery. Products made in a GMP certified facility can state such on their packaging, yet the FDA has yet to officially approve of any CBD or THC products at the federal level.

Therefore, your facilities should aim to implement its own high-quality GMP until either your state, local, or federal government publishes regulations. Not only will this allow you to set your pre-rolls above the competition, but it’ll help you stay ahead of the curve for whatever regulations may eventually be put into place over the cannabis industry at the federal level.

GMP is important beyond regulatory reasons because it allows you as a business owner to ensure a level of quality at every step in the process, from selecting your pre-rolls paper to filling and packaging.

How Does GMP Relate to Quality?

For most business owners, GMP is viewed as a way to control the quality of production at every level more than regulation. The standards are designed to ensure that each product is of the same level of quality and that they are safe and effective.

In pre-roll facilities, it would relate to how high quality each step of your rolling process is. This includes internal rules for material quality, equipment maintenance, staff training, and quality control. Once you’ve established your own GMP standards, it will be much easier to adjust to the state or federal GMP regulations that may eventually be rolled out.

How Are GMP Facilities Tested?

While the FDA has previously stated that they are willing to consider reclassifying CBD, there are currently no pre-roll, CBD, or other cannabis-related facilities being tested by the government. Therefore, while your pre-roll facility cannot currently be tested for GMP certification, in the future, it may involve paperwork, regulators coming on-site to test your facility, and view your practices, and record-keeping as it does with other industries.

However, each state will have its own testing requirements for facilities. It’s important to keep in mind your local regulations as well, which can go far beyond just extra taxes. Make sure your facility is up to date and keeps good records, clean and safe storage, and follows safe and effective employee training habits.

Should I Worry About GMP Certification?

As a pre-roll facility, you won’t need to worry about FDA regulations or tests just yet. Until the federal government legally recognizes cannabis use and the FDA publishes cannabis industry-specific GMP, you won’t be able to gain a true GMP certification. This means you can worry more about getting your pre-rolls to market and less about cleaning up for FDA inspectors.

However, you can prepare your facility and employees for the future by implementing smart, safe, and practical GMP standards now to help you meet local and state regulations. Focus your efforts on making sure there are a set of processes and records for every step in production that your pre-rolls take. This allows you to track the quality and prepare for any eventual FDA or state quality tests.

How Do I Implement Good Manufacturing Practices?

To start, look at the steps you and your employees already take during each phase of the manufacturing of your pre-rolls. How do you acquire cannabis, and how is it stored until it’s ready to be rolled? How often is your equipment maintained, and should it be maintained more often?

Go through your facility and ask yourself the questions a regulator would, looking for areas of improvement or where you should tighten up your standards instead of doing whatever works on that day. The more you can plan out for each step of the process and have documented, the better off your facility will be if the FDA implements GMP for the cannabis industry.

Because there’s no federal oversight of pre-roll facilities today, it’s more important than ever to take responsibility as a business owner to do your part to ensure the health and safety of your customers. By taking the time to implement your own GMP and place extra emphasis on the quality of your pre-rolls, you’re ensuring that there are more quality products out on the market to outweigh the shady companies that take advantage of the lack of regulation.